Energy Efficiency

U

sing a digital predictive model, we can simulate and analyze the energy efficiency of a component, product or system by applying tools based on bond graph theory.

We are then able to calculate the energy consumption of different components or specific subsystems, and also identify the power losses and inefficiencies during critical duty cycles, which allows us to suggest energy-optimized efficient design alternatives.

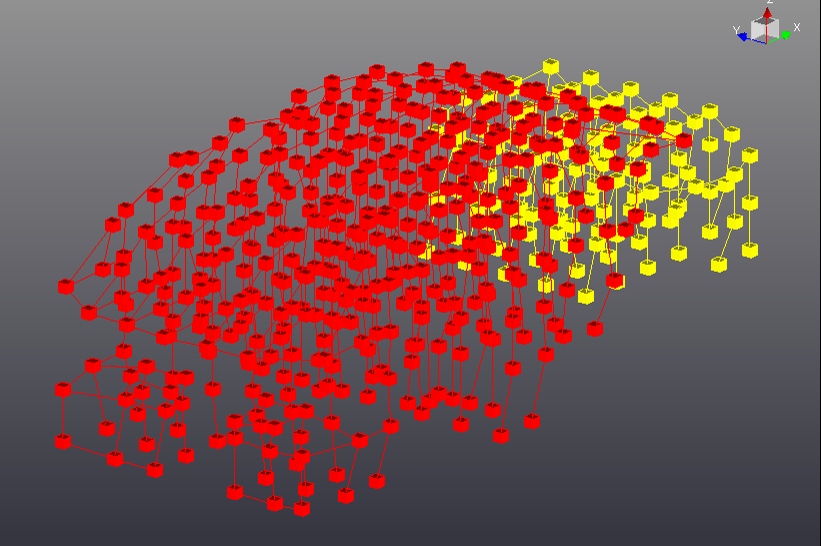

Noise and Vibration Analysis

I

n noise and vibration analysis, we employ linear analysis to study the natural frequencies of a system to determine the causes of undesired high-frequency vibrations, fluid-, structure- and air-borne noise or noise transmitted due to modal couplings.

Noise and vibration analysis can be used to:

- suggest various methods to reduce the excitation from the source;

- find resonances in the system and tune it so as not to excite said resonances;

- evaluate the influence, behavior, and contribution of mounts, couplings, isolators, etc. that are employed to reduce the transmission of noise or vibrations;

- understand the dissipation of the noise or vibration energy;

- optimize the properties of acoustic materials such as cabin interior linings, etc.;

- get insights into the loads and deformation of parts and components to prevent fatigue cracking and increase durability.

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)