Battery Testing

n recent times the need to reduce CO2 emissions into the atmosphere has increased the interest in electrified systems.

Among the various energy storage systems, electrochemical batteries are preponderantly used in most industrial sectors such as automotive, aerospace, naval, and photovoltaic to name a few.

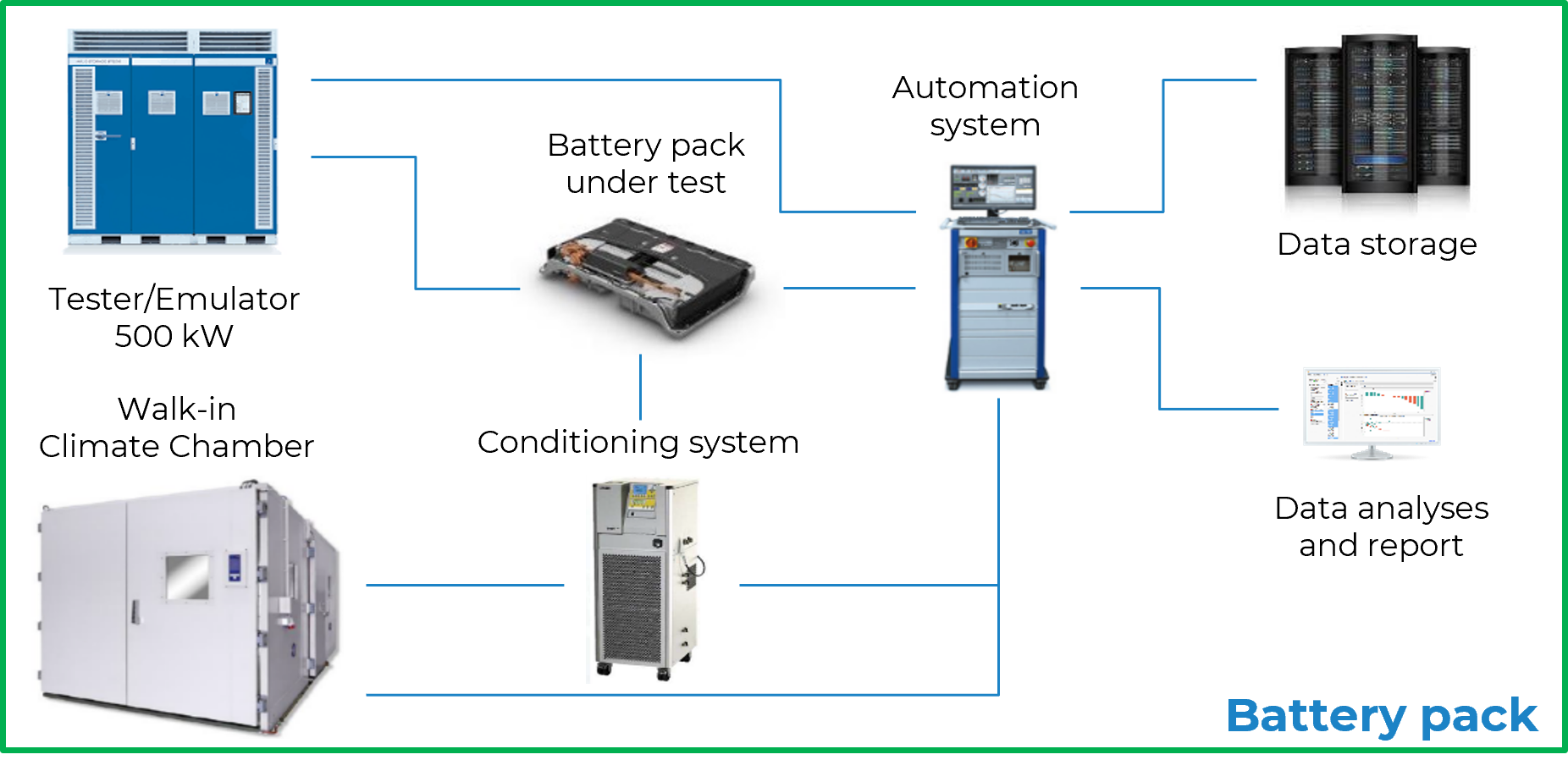

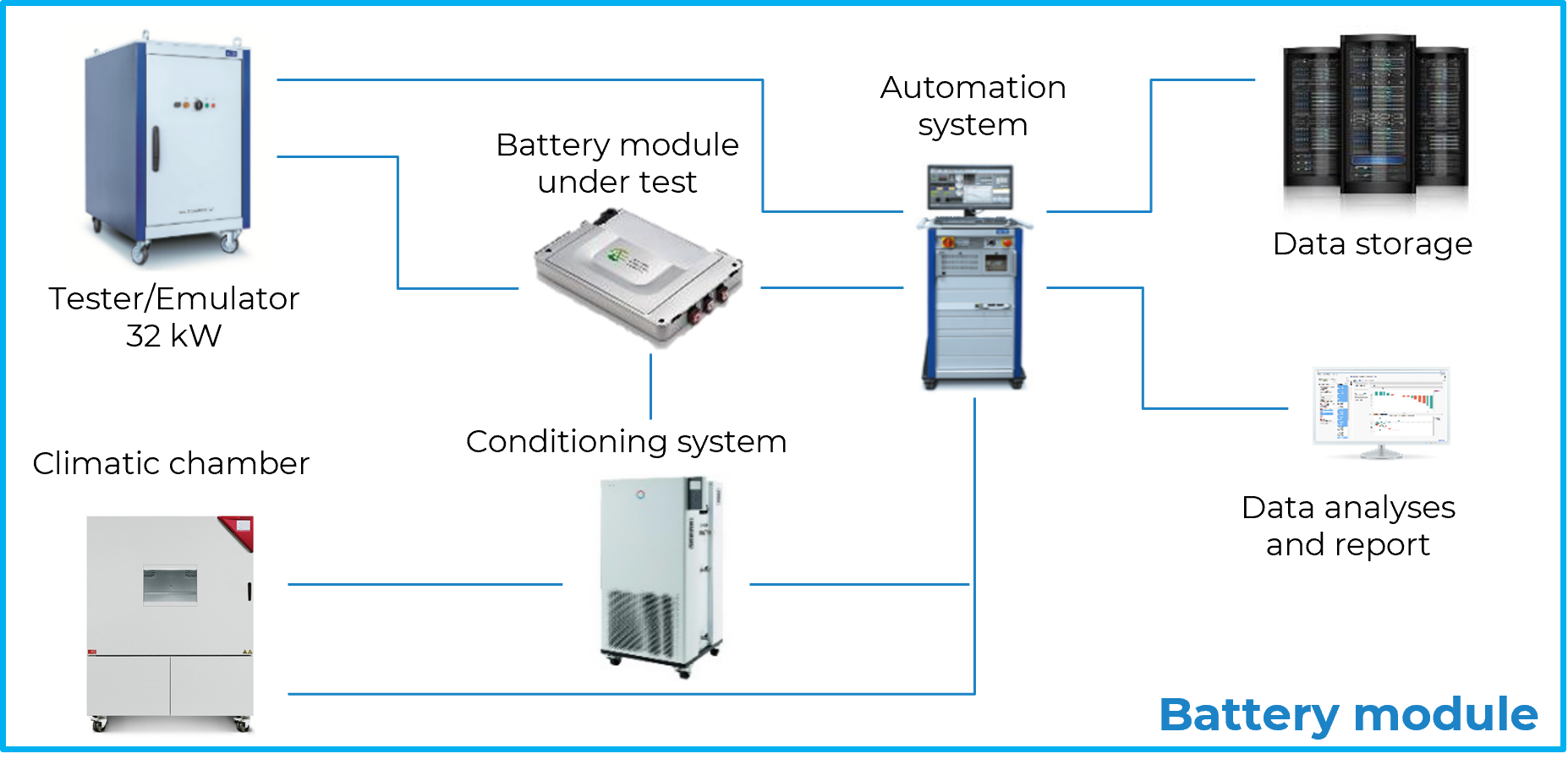

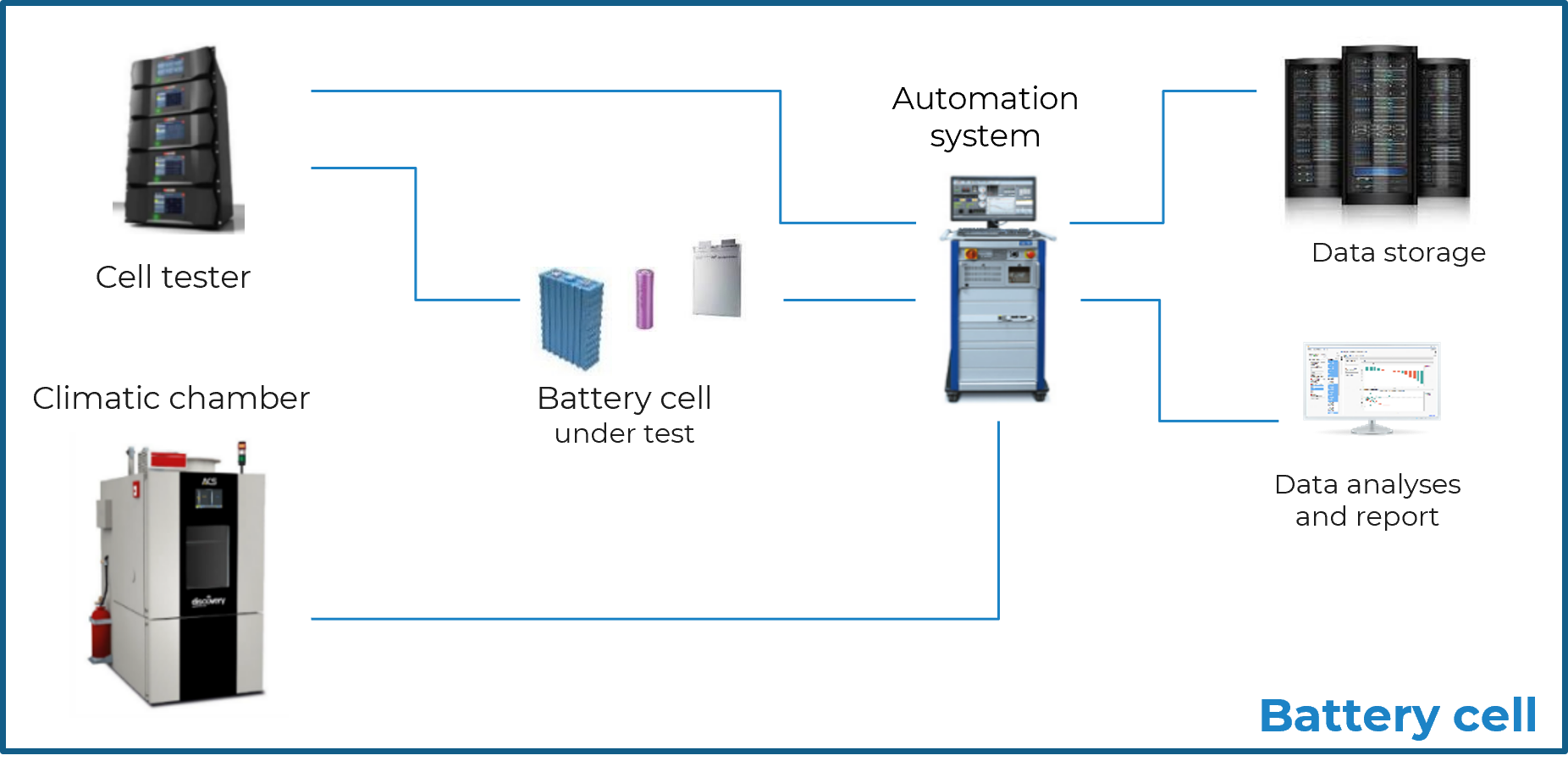

With our battery test facilities, we aim to test and validate the vast majority of electrochemical batteries intended for various uses and applications, preeminently lithium-ion batteries.

Our extensive range of tests can be

run on single battery cells, modules, and large packs ensuring voltage and power levels

in full compatibility.

We also can perform charge/discharge tests with configurable current and temperature profiles according to standards or customer specifications up to hazard levels 5 in compliance with EUCAR classification.

A powerful air conditioning system allows us to carry out thermal management studies and assessments as well.

Following, are some examples of battery tests:

- Static capacity

- Capacity fade

- Hybrid power pulse characterization (HPPC)

- Self-discharge

- Cold-cranking

- Thermal performance

- Energy efficiency

- Cycle life

- Calendar life

Battery test systems

Main features

- Tests on battery packs up to 1200 V, 500 kW

- Tests on battery modules up to 60 V, 32 kW

- Tests on battery cells up to 6 V, 3,6 kW (per channel)

- Tests in climatic chamber

- Tests with temperature control units

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)