Noise, Vibration and Harshness (NVH)

Acoustic emissions and vibrations strongly influence the value and quality of a product.

The containment of noise is essential to comply with increasingly stringent regulations. Vibrations, in addition to reducing comfort, induce fatigue and contribute to generate structural critical issues.

We employ various hardware and software solutions for the acquisition and analyses of vibro-acoustics phenomena mostly in the following fields:

NVH – Acoustic Testing

During the operation of a machine, it may be necessary to monitor the noise emission levels both to ensure its correct functioning and evaluate the acoustic comfort of the surrounding environment.

We are able to measure and assess the acoustic performance, sound pressure and sound power levels of a machine or a product and support the customer by developing improvements and optimized solutions.

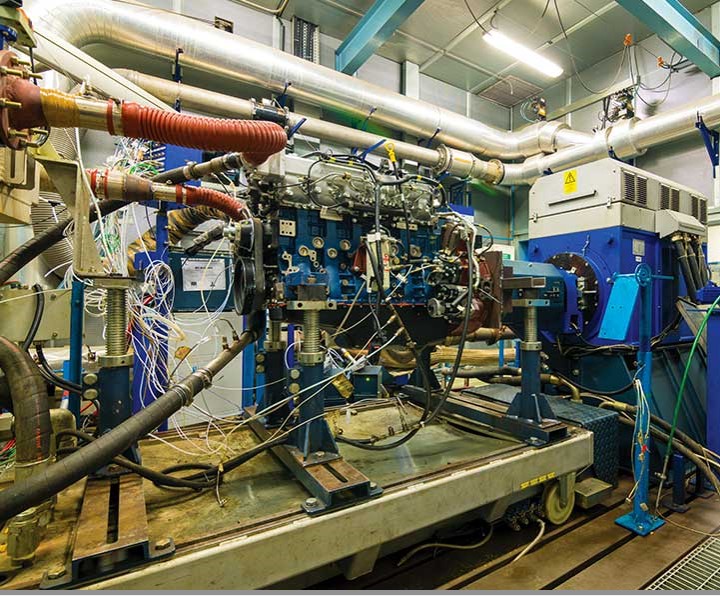

NVH – Durability Testing

With our durability test techniques, we are able to determine the characteristics of a system subjected to variable loads over time or to various load conditions. These loads determine whether a system is infinitely durable or may only serve for a certain amount of time or number of duty cycles.

In the automotive application, we acquire and analyze the loads and fatigue of a vehicle and the road load elements.

NVH – Environmental Testing

We are able to perform tests in different climatic and environmental conditions by reproducing temperatures, shocks, particular stresses, and extreme vibrations to safeguard proper system behavior in all situations.

NVH–based End of line testing (EoL)

End of Line vibroacoustic tests are intended to verify and ensure that a product complies with technical specifications, as well as with vibroacoustic performance and quality requirements.

Through these fully automated and very fast tests, the components that do not fall within predefined thresholds can be collected and reviewed for new validation. The product vibroacoustic quality standards are usually provided by manufacturers or collected via feedback from customers or end users.

We support manufacturers from the early definition of the admissibility thresholds, carrying out tests and measurements, reading the output data, and validating each product taking into account their peculiar acoustic response.

Provided a positive outcome of the validation, only the items that meet the specifications will be reintroduced into the manufacturing cycle and delivered to be assembled.

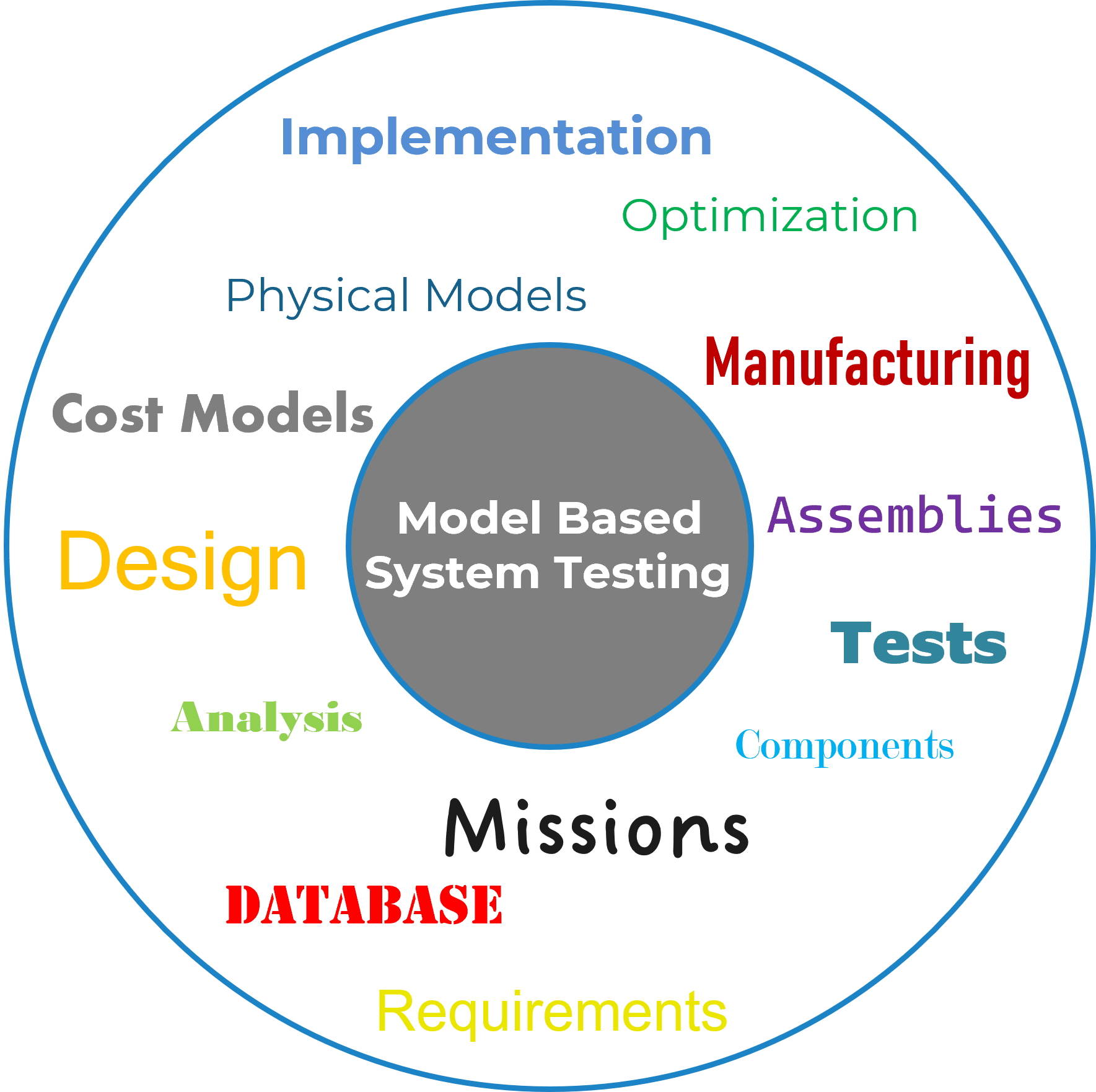

NVH – Model based system testing

We are able to implement and correlate tests and simulations in a single environment to provide a complete and specific assessment based on both virtual models and physical tests. This interdisciplinary combination reduces time, cost, and errors in all phases of product development and validation.

Simulation frontloads the development cycle and reduces the necessary physical testing while the subsequent test data is fed back into the models to improve their accuracy.

NVH – Rotating machinery testing

We are able to perform NVH tests to monitor and control parameters such as speed, torque, torsional vibrations, etc. in order to optimize and maximize the efficiency and the quality of rotating machines and the environment in which they operate.

NVH – Sound Design & Sound Quality

Apart from a specific brand sound, the noise from any system has another subjective quality. Recent studies show an important correlation between sound and perceived sound quality, which is why sound design and acoustic tests have become an integral and important part in the development process of many products currently on the market.

The area of sound quality is not only limited to systems with active loudspeakers, but also to mechanical systems whose sound can be optimized to create a more pleasant “noise”.

NVH - Structural dynamics testing

With our structural dynamics test methods, components can be evaluated at every stage of design, even in high-stress and high-performance environments.

We support our clients to create and develop comprehensive test programs and campaigns to ensure the reliability and safety of a product throughout its life cycle.

Modal Testing

We manage acquisitions and analysis, to the frequency responses functions (FRFs), natural frequencies and modal shapes of the system.

Experimental Modal Analysis

To describe, assess, and model the dynamic behavior of a structure, including its natural frequencies and mode shapes. (performed in lab conditions).

Operational Modal Analysis

To identify the modal properties of a structure during operating conditions and collect vibrational data. (performed during normal operation).

Vibration Troubleshooting

Root cause analysis to identify the cause of abnormal vibrations/frequencies and possible solutions.

NVH – Transfer Path Analysis (TPA)

Modern machines increasingly use different innovative materials and different assembly techniques that can modify the normal propagation of vibrations and noises.

With the use of a Transfer Path Analysis (TPA) we are able to identify loads, forcing and source emissions, transfer and response functions in key positions to optimize products at every design level.

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)