Layerloop

Additive Manufacturing with Flexibility and Precision

With Layerloop, Dipolo brings a new generation of additive manufacturing systems to industrial and medical applications.

As an authorized partner of Smart Lab Industrie 3D, Dipolo provides the entire Layerloop portfolio, including the XE 200, NEXT, and EXTEND models, designed for continuous, precise, and flexible 3D printing.

Each Layerloop system combines mechanical innovation with practical usability, featuring the brand’s signature 30° inclined printing axis for support-free printing and uninterrupted production cycles.

Why Dipolo + Layerloop

Authorized partner and technical reseller for the complete Layerloop range

Specialized expertise in the Layerloop XE for medical and research applications

Training, installation, and application consulting by experienced engineers

International support and distribution beyond the DACH region

Layerloop I.M. Slicer: Continuous 3D Printing and "Infinite" Production.

Non-Stop Production: The slicer utilizes the 30° inclined axis and the conveyor belt, enabling potentially unlimited length prints (Z-axis) for 24/7 automatic batch production.

Zero Support Waste: Thanks to the optimized angle, drastically reduce or eliminate the need for support structures, saving material and post-production time.

Smart Object Functionality: Print preparation for "smart" objects with the capability to integrate RFID/NFC Tags directly inside the model.

Full Material Freedom: The open system managed by the slicer supports a wide range of industrial polymers (up to 400°), from flexibles to composites.

Product Overview

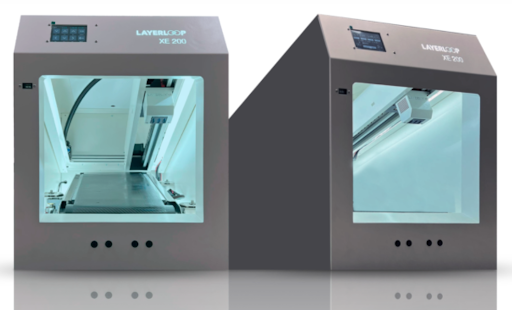

Layerloop XE 200 – Flexibility for Industrial Applications

The Layerloop XE 200 is a compact, open-chamber 3D printer designed for precision, flexibility, and ease of use.

Featuring the brand’s distinctive 30° inclined printing axis, the XE enables support-free fabrication and exceptional surface quality, even with flexible or soft materials.

It’s the ideal entry-level solution for industrial users or professionals who require a versatile, reliable, and high-performance additive manufacturing system.

Originally developed for medical and orthopedic applications, the XE 200 excels in producing custom insoles, orthoses, and functional prototypes made from elastic materials with consistent accuracy and durability.

Key Features

Processes flexible, rubber-like materials with ease

Support-free printing with 30° inclined axis

Compact and robust design for laboratories or clinics

High repeatability and surface precision

Low-maintenance operation with open material compatibility

Ideal for

Medical and orthopedic applications (e.g. custom insoles, braces)

Research laboratories

Design studios and prototyping environments

Layerloop NEXT – Continuous Production, Redefined

The Layerloop NEXT represents the next generation of continuous 3D printing.

Its tilted build axis and belt-based print system allow for endless production of parts without operator intervention.

This makes the NEXT an ideal solution for companies seeking to combine automation, flexibility, and sustainability in small- to medium-scale series manufacturing.

Designed for high uptime and versatility, the NEXT can process over 15 different materials, from standard polymers to high-performance engineering plastics, making it a true workhorse for industrial and research environments.

Key Features

30° inclined axis for support-free, continuous printing

Unlimited part length through conveyor belt design

Compact footprint for office, lab, or small production environments

Compatible with a broad range of technical materials

Designed for 24/7 automated operation

Ideal for

Small series and continuous production

Industrial design and prototyping

Educational and research facilities exploring automated AM

Layerloop EXTEND – Precision without Compromise

The Layerloop EXTEND is built for professionals who demand maximum accuracy and stability in every print.

Equipped with a heated and fully enclosed build chamber, it ensures consistent results across complex geometries and advanced technical materials.

Its modular structure makes the EXTEND adaptable to a wide range of applications, from functional prototyping to low-volume manufacturing and materials research.

Engineered for industrial environments, the EXTEND combines process reliability, repeatability, and scalability, making it an excellent choice for companies that require professional-grade additive manufacturing.

Key Features

Heated build chamber for stable and uniform temperature conditions

Optimized for high-performance polymers and composites

Precision mechanics for consistent dimensional accuracy

Modular configuration for customized setups

Ideal for demanding industrial or research environments

Ideal for

Technical prototyping and functional testing

Small-series production

Advanced material research and development

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)